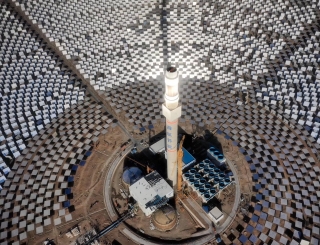

A circular array of flat computer-controlled heliostats concentrates sunlight on to a central receiver at the top of a tower. Molten salt in the receiver acts as a heat transfer medium and absorbs the thermal energy and transfers it into the steam cycle to generate superheated steam for the turbine.

The advantage of tower systems over the parabolic trough (PT) or Fresnel collector concept is that the sunlight on the central receiver is focused on to a smaller area, and the heat transfer medium does not have to be piped around the large solar field. This means that higher working fluid temperatures in the receiver (up to 565°C) and better steam parameters are possible, with even supercritical steam feasible.

High-precision Intelligent Heliostat Properties

Working Wind Speed: 24m/s

Survival Wind Speed: 40m/s

Working Temperature Range: -40℃ ~ 65℃

Ingress Protection: IP65

Working Altitude: ≤5000m

Reflectivity: 94%

Accuracy: 1.65mrad

Annual Failure Rate: <0.5‰

Maintenance: No Lubricant Replacement Needed

Function: Auto-concentrating, Auto-dispatching, Auto-calibrating, Self-diagnosis

Third Party Verification: Tracing Accuracy Verification, Environment Adaptability Verification, CE Certificate

Heliostat Field Control System

Supported Scale in the existing project

About 12,000 sets of heliostats, 2.4 sq.km. reflecting area, 1.5km heliostat-tower distance

Security features

Redundant power-supply and communication of control system

Heliostat Array System Suite

The Helix Array System Suite is at the heart of the communication and control of the heliostat field, enabling perfect data acquisition control, efficient transmission and safety security.

• IP65, natural heat dissipation

• Lightning protection, anti-surge

• Ambient operating temperatures from -40°C to 55°C

Controlling redundant power supply and integration of the internal controller

Helix Group System Suite

The Helix Group System suite is the administrative brain of the heliostat field communication and management, optimizing intelligence, efficiency, security and reliability.

- IP65, natural heat dissipation

- Installed with 3000V AC/DC power

- Operating from -40°C to 75°C

Software

The Helix field control system has built-in configuration software, monitor software, advanced control software and system tool software, combining self-managing functions such as dispatching, monitoring, maintaining and upgrading the Helix heliostat field devices.

Calibration of the Helix System

- There is an automatic calibration system, and no manual operation is required

- High-precision: High-precision tracking ensures efficient energy production

- Constant intelligent, automatic accuracy check and periodical auto-calibration

The HELIX-Tower Thermal Receiving System

The receiver is the central part of the thermal receiving system, it absorbs solar energy and converts it into thermal energy by heat transfer media.

The Helix molten salt receiver has to sustain frequent and sharp temperature fluctuation and corrosive condition. To overcome such working conditions, Pacific Green has optimized the receiver design using computational fluid dynamics to ensure safe operating parameters.

Key Features

Receiver Material

Heat-resistant, anti-corrosion, thermal stress & fatigue resistance

Durable Structure

Thermal stress & fatigue resistance

Safe Operating Process

Anti-freezing, energy dispatching, temperature monitored

Parameters of the Molten Salt Receiver

Receiver Type: MSR

Material: Inconel Alloy 625 / Haynes Alloy 230

Coating: Black Pyromark Coating 2500 Series

Absorptivity: ≥94%

Efficiency: ≥91%

Top Energy Flux Density: 1200kw/㎡

Operation & On-off Safety Strategies

Preheating

Heating and maintaining optimum temperature

Salt Infusing

Preventing solidification

Temperature Rising

Controlling surface temperature rising rate, diagnosing and melting frozen salt

Stable Operation

Maintaining outlet salt temperature at 565℃

Cloud Blocking

Mitigating thermal shock

Salt Draining

Preventing solidification