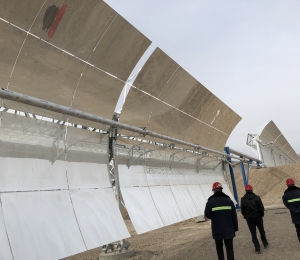

This system is based on the capture of solar energy through a parabolic trough collector that allows the heating of a heat transfer fluid for the use of the heat in a conventional thermal cycle.

The reflector concentrates solar radiation in a central collector tube through which thermal oil circulates. The temperature of the PARABOL-Trough™ receiver is up to 400℃

Key Features

Safe and reliable process flow

- Anti-freezing, leakproof

- Intermittent operation, frequent on-off

- Coordinated control of energy variation

Customized equipment with high reliability

- Frequent on-off capability

- High tolerance of thermal stress and fatigue

- Built-in heat and corrosion resistance

Reflector

The PARABOL-Trough™ reflector is designed with maximum torsional structural stiffness, lightness and ease of construction. The mirror surface is accurately and consistently factory produced to a high level of accuracy, with a very efficient reflectivity and easy to clean surface.

Characteristics

The receiver tube has the toughness and chemical resistance to cope with extreme weather conditions, as well as good light transmittance performance.

The metal absorber tube absorbs the sunlight to heat the heat transfer fluid inside. In between the glass tube and the metal tube is vacuum in order to reduce the heat loss.

After passing through the receiver, the heat from the high temperature oil can be stored or used to vaporize water which, by expanding in a steam turbine, drives an electric generator that injects energy into the network.

Control system

There is a high precision optical sensor that tracks the sun from east to west focusing.

These sensors, developed and qualified by Pacific Green Solar Technologies, incorporate new design improvements that reduce the cost of energy collection and construction of the plant.

Storage

The PARABOL-Trough™ system transfers the heat from the hot oil to the THERMO-Store™ heat reservoir tank.